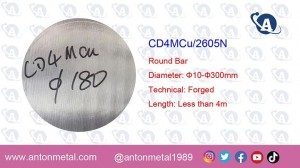

CD4MCu/2605N Round Bar

Alloy CD4MCu is basically ferritic, its yield strength is about twice that of 19Cr-9Ni austenitic alloy, and it has high hardness, good tensile plasticity and satisfactory impact toughness. The alloy’s high strength and hardness combined with excellent corrosion resistance make it especially suitable for use under corrosive (including abrasive and erosive) working conditions. The corrosion resistance of alloy CD4MCu in many corrosive media is better than that of CF alloy. It is used in strong acid working conditions of oxidation and reduction, and has special resistance to stress corrosion cracking in chlorine-containing environments. After solid solution treatment, CD4MCu alloy can be further strengthened by precipitation hardening at 480-510°C. The degree of aging reaction, as well as all properties of the alloy in the aging state, the rest including corrosion resistance, strength, impact toughness and quenching cracking tendency are related to the multiphase treatment method, that is, the solution treatment temperature, aging temperature and aging time related. Because the alloy has sufficient strength and excellent corrosion resistance for many applications after solution treatment, it is not often used in the aged condition.

D4McuN Chemical Composition:

|

C |

Mn |

Si |

P |

S |

Cr |

Ni |

Mo |

Cu |

|

≤0.04 |

≤1.0 |

≤1.0 |

≤0.04 |

≤0.04 |

24.5-26.5 |

4.75-6.0 |

1.75-2.25 |

2.75-3.25 |

CD4MCu physical properties:

Density: (g/cm2) 7.8

Elastic modulus (MPa×103): 210

Thermal conductivity (W/m.C): 13.5

Linear expansion coefficient (×10-6/°C): (20~100°C) 12.3

2605N is one of the duplex stainless steel series. Like all duplex steels, 2605N has a greater tendency to precipitate intergranular substances than austenitic stainless steel. The σ phase will be formed at a temperature of 700-1000°C, and the embrittlement at 475°C will be formed at a temperature of 350-525°C. However, after normal welding and heating, the microstructure does not contain any harmful precipitates or metal phases that can cause embrittlement, and it is commonly used in instrumentation.

2605N metallographic structure:

When 2605N is solution annealed at 1050~1125℃ and rapidly water-cooled, its microstructure generally contains 30%~50% ferrite and austenite balanced with it. When the operation time from annealing to quenching is short, lower temperatures should be used. If annealed at higher temperatures followed by immediate rapid cooling, the ferrite content will increase and there is a risk of nitride precipitation.

CD4MCu mechanical properties:

CD4MCu steel has high strength, high fatigue strength, good plasticity and cold forming properties, and has good resistance to pitting corrosion, crevice corrosion, intergranular corrosion and uniform corrosion resistance.

CD4MCu processing performance: Since CD4MCu steel contains copper, the hot working temperature of the steel should not be too high, and the final forging temperature is generally about 980 °C. The steel can be sheared, stamped, molded, etc., but due to the high strength of the steel, the deformation force of cold working is 2~3 times higher than that of austenitic stainless steel. If the steel is heated to 200°C, the yield strength can be reduced by 25%, which can make the forming process easier. The steel can be welded with various shielded welding, it can be welded with other grades of duplex stainless steel, and it can also be welded with dissimilar steel (non-stainless steel) or non-alloy steel.

CD4MCu corrosion resistance: The pitting corrosion resistance of CD4MCu steel is better than other Cr18-5Mo duplex stainless steel, better than austenitic stainless steel 00Cr17Ni14Mo2.

CD4McuN material duplex stainless steel structure and type

CD4McuN material duplex stainless steel has the characteristics of austenitic stainless steel and ferritic stainless steel because it has austenite + ferrite duplex structure, and the content of the two phase structures is basically the same. The yield strength can reach 400Mpa ~ 550MPa, which is twice that of ordinary austenitic stainless steel. Compared with ferritic stainless steel, duplex stainless steel has high toughness, low brittle transition temperature, significantly improved intergranular corrosion resistance and welding performance; at the same time, it retains some characteristics of ferritic stainless steel, such as 475 ℃ brittleness, thermal High conductivity, small coefficient of linear expansion, superplasticity and magnetism. Compared with austenitic stainless steel, the duplex stainless steel, especially the yield strength, is significantly improved, and the pitting corrosion resistance, stress corrosion resistance, fatigue and other properties are also obvious.

CD4McuN material duplex stainless steel welding characteristics.

CD4McuN duplex stainless steel has good welding performance. Compared with ferritic stainless steel and austenitic stainless steel, it is neither like the welding heat-affected zone of ferritic stainless steel, but the plasticity and toughness are greatly reduced due to severe grain coarsening , and unlike austenitic stainless steel, it is more sensitive to welding hot cracks.

Welding performance problems often occur in economical “CD4McuN material duplex stainless steel”. Welding standard duplex steels is not an issue, and there are consumables for these applications regardless of the process used. From a metallographic point of view, welding 2101 (1.4162) is no problem at all, in fact it is even easier to weld than standard grade duplex steel, because this material can actually be welded with acetylene welding, while This process is always avoided for standard duplex steel materials. The practical problem with welding 2101 is that the melt pool has a different viscosity and therefore is a little less wettable. This forces operators to use arc welding more and more during the welding process, which is where the problem lies. Although this can be remedied by selecting superalloyed consumables, we often wish to select matching consumables.